Turkish startup turned machine failure into a business model

Airways and railways have been conservative and difficult sectors for startups due to safety and security issues. But this is changing, especially when it comes to support services and maintenance.

Delphisonic, a Turkish startup launched in 2015 by Ali Acur, is one of the gamechangers. The startup harnesses big IoT data to provide predictive maintenance for companies in different countries and sectors, including railways, wind turbines, and airways.

Acur started working on this concept in 2012, after leaving his job as a mechanical preventive maintenance engineer at Airbus Germany. He believes that companies are willing to invest in predictive maintenance because “it can increase equipment lifetime, reduce maintenance costs and time, increase vehicle safety, and eventually save lives”.

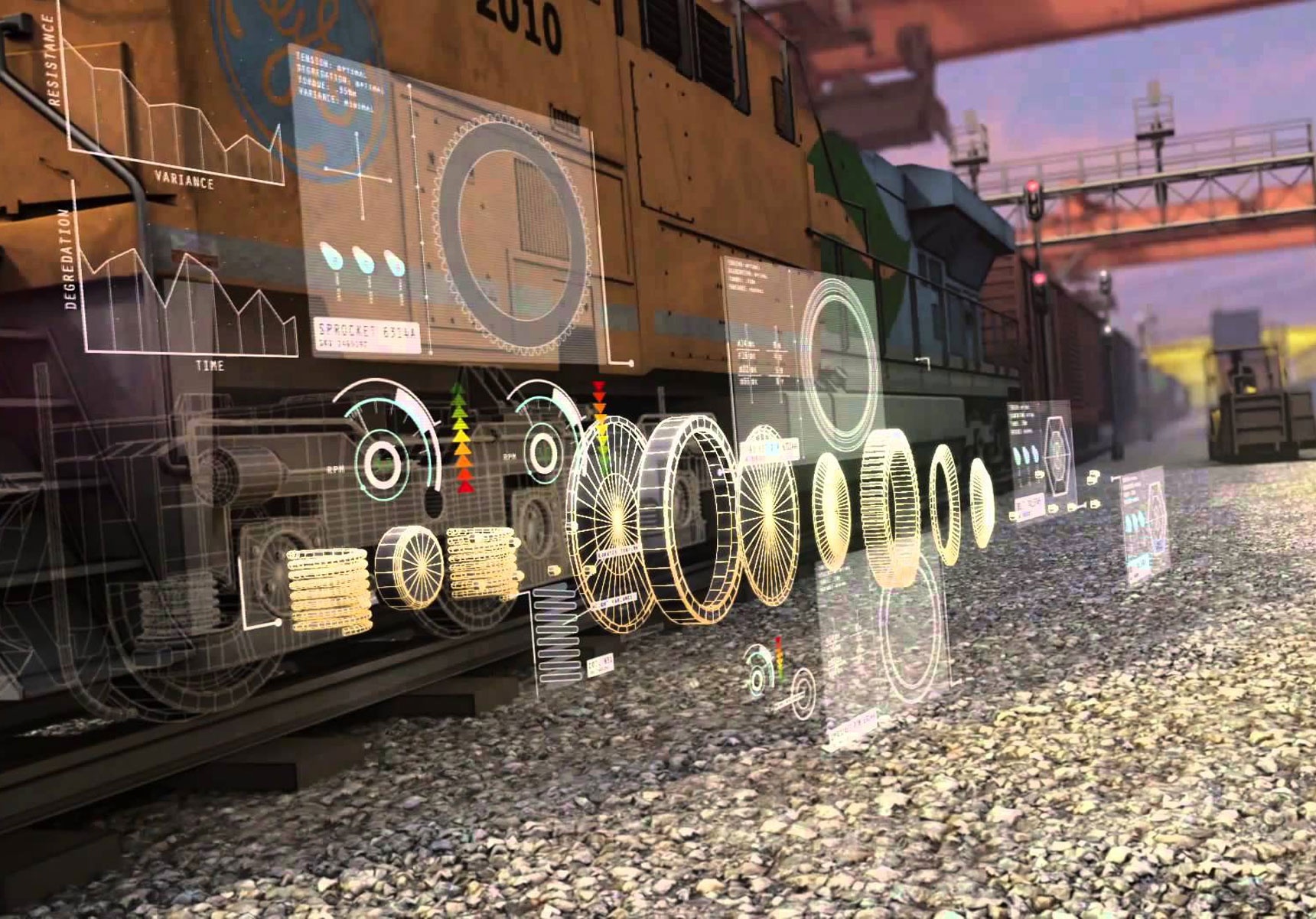

The real time condition monitoring system consists of connected sensors, a connectivity device, and a software.

Delphisonic can be attached to the machines with sensors to collect different data: vibration, speed, pressure and temperature. The system sends this data to a cloud system or internal server and visualizes it as reports so the maintenance team can monitor and get alerted if there is any abnormal record. It can also be integrated with the enterprise’s system.

(Images via Delphisonic)

The system doesn’t define what the problem exactly is, but shows that a problem is going to happen soon. “The sensors track the performance of a wheel. If it records a high vibration level, for instance, it means that there is an unbalancing problem and you need to replace it within two or three weeks,” Acur told Wamda.

The product is provided as a SaaS with no upfront charge, but with a minimum contract period of 24 months. During this period, Delphisonic maintains and repairs its system every six months, and provides detailed reporting and resolution services on a monthly basis.

Acur said that the cost depends on the industry. The system can be installed on different industrial machines such as locomotives, production lines, and ships among others.

For instance, you pay for a railway predictive maintenance system for one locomotive 50,000 euros (around US$ 60,000) per machine. “This is a low cost product when it comes to such big industries,” he added.

Marketing via partnerships

The Turkish entrepreneur said that his startup was facing challenges when it comes to marketing its product. They tried product demo marketing and it worked.

“After developing the prototype, we needed to proof our concept,” said Acur. “In 2013 we approached Turkish State Railways (TCDD) to connect Adana Mersin railway-line with our system in a promise to decrease maintenance costs.” After trying the system for six months, they became one of the startup’s first clients.

The startup’s client list now involves 20 companies, including the TCDD and other companies in Turkey (freight company U.N RO.RO), in the US (National Railroad Passenger Corporation, Amtrak), in Germany (national rail company DB Bahn), and in Switzerland (SBB cargo).

Predictive maintenance is expected to help companies save $630 billion by 2025. Many large corporates are now invading the asset management and maintenance field such as IBM, GE and Bentley.

“These companies are our main competitors”, said Acur. “But we are partnering with them to make a win-win deal.”

Delphisonic has partnerships with GE Turkey to connect its system to GE’s Predix (the industrial IoT platform), and Microsoft to connect to Azure.

“As a big industrial company, GE can leverage our system in many ways. In addition their platform, they can be our ‘bridge’ to European, MENA, and US markets.”

Future steps

“The market is full of potential but what holds us back now is that we are manufacturing in Turkey in a small workshop,” said Acur.

“Having a faster and bigger production line will help us cater for a bigger number of clients and expand our reach,” he added.

The company was bootstrapping until it got a seed investment of $40,000 from The Scientific and Technological Research Council of Turkey (TÜBİTAK), which has a program to promote and fund national and international patent applications of Turkey. Then, in 2015, a US angel investor joined with more than $100,000 according to Acur.

The startups is not breaking even yet, but has made $1.5 million in revenues last year, Acur said. “We are looking for a Series A investment,” he added.

“We are a team of 11. I am the founder but I also work as a sales representative. Hiring more people will help me focus on our core business, expand to other countries and other sectors such as oil and gas,” Acur said.